With many European countries such as Germany, the UK and France set to ban all fossil-fuel powered vehicles between 2030 and 2040, the drive towards electrically powered vehicles is rapidly accelerating. At the forefront of this push is the battle between the more traditional and well-established lithium-ion batteries and the exciting new technology of graphene batteries.

What are lithium-ion batteries?

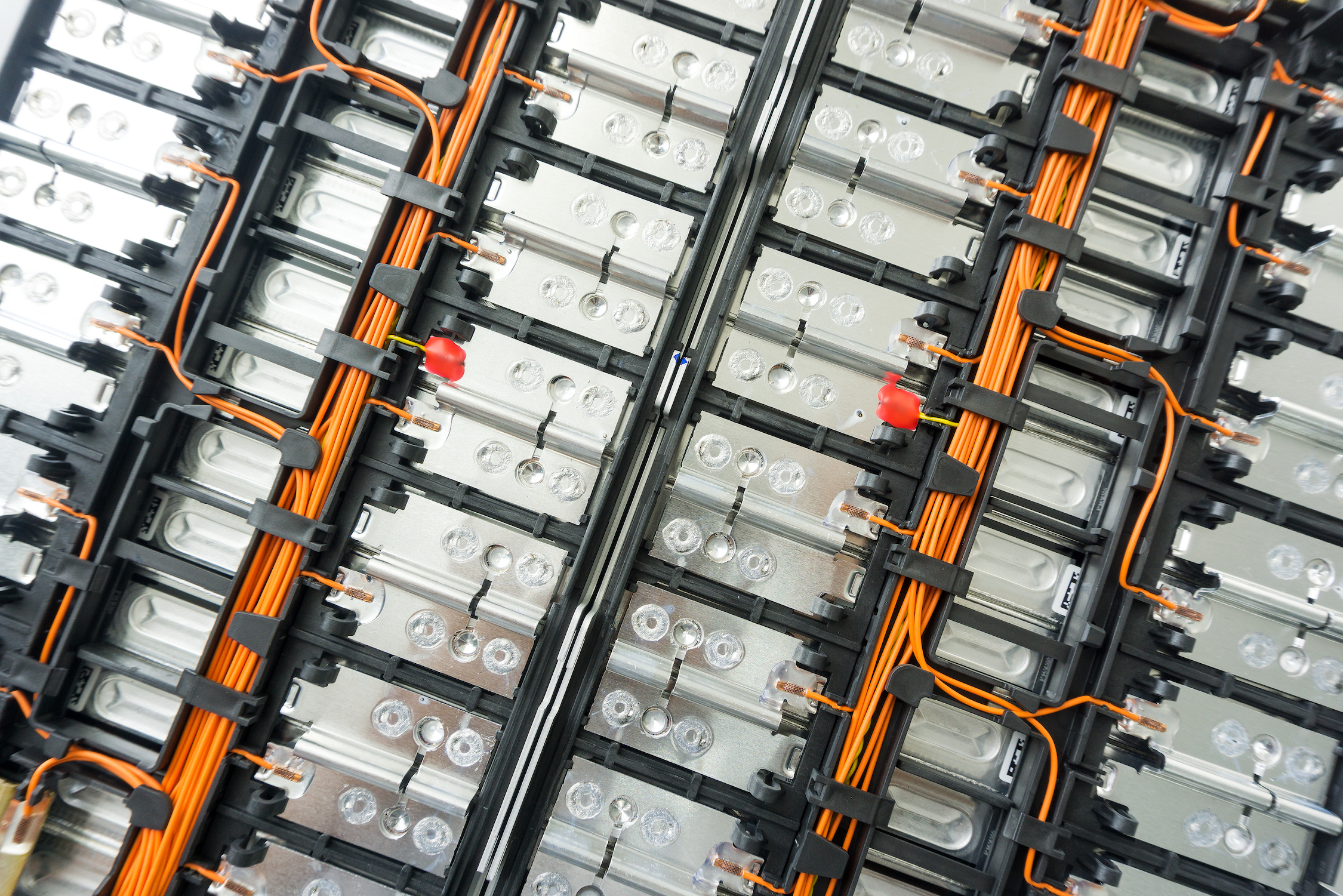

Lithium-ion batteries are currently used in almost all electronics, from smartphones and computers to speakers and practically all electric vehicles.

The basics of a lithium-ion battery include an anode and cathode (which contain the lithium) and an electrolyte to carry the positively charged lithium ions between the anode and the cathode through the separator. While this setup has appeared the most effective way to store and recharge electrical energy since its inception in the 1970s, graphene batteries seek to dethrone lithium-ion batteries, particularly when it comes to safety.

The aforementioned separator is important to keep the two electrodes from meeting, which would quickly heat up and become explosive if they were to touch. This is a clear safety concern, especially since said separator is usually a thin and porous slip of polypropylene, and this is such an issue that AFAA (American Federal Aviation Administration) banned them as cargo on passenger planes.

What are graphene batteries?

Graphene batteries remove the safety issue of lithium-ion batteries almost completely, as one of the electrodes in the battery is replaced with a hybrid composite material which must include graphene, making an explosion at the contact of the two electrodes extremely unlikely.

Safety, however, is not the main selling point of graphene batteries. While lithium-ion batteries are famous for their high weight to capacity ratio, Graphene as a material is extremely lightweight, and due to its thin, flat, and hexagonal structure, it is also an excellent conductor of energy and electricity. Despite being thin, it remains extremely strong (notably stronger than diamond or steel).

Graphene vs lithium-ion batteries: the verdict

Graphene batteries have been proven to have a much higher capacity on average than lithium-ion batteries, even at smaller sizes. Lithium-ion batteries can store up to 180Wh per kilogram, while graphene can store up to 1,000Wh per kilogram, making it a much more space-efficient store of energy. This, of course, means that for vehicles, a graphene battery is not only safer in the event of a crash, but it can also provide a much longer range on a single charge with a smaller, lighter battery. Due to their flat, easily conducting structure, graphene batteries even charge much faster and dissipate excess heat more effectively.

All this suggests that graphene batteries are most definitely the future of electric batteries for trucks, and indeed all battery technology. There is, however, one singular and extremely important factor holding this new technology: cost.

Graphene is and remains for now, extremely expensive to produce on mass. Thus, the future of graphene and its batteries relies entirely on the production cost being brought down. Companies such as Samsung are investing heavily into doing so, and while the results appear promising, only time will tell if a cheaper method of production can be found.

In the meantime, many battery producers have been moving to an intermediate, attempting to blend graphene technology into pre-existing lithium-ion batteries to improve their capacity and effectiveness for a lower cost, though these are relatively new and still not commercially available.

If you’re looking for commercial vehicle sales, truck parts sales or other related vehicle services, get in touch with our team at James Hart (Chorley) Limited today.